The Washington State Department of Transportation’s (WSDOT’s) Target Zero highway safety program was developed to reduce fatal and serious crashes across the state in the most economical and efficient manner. WSDOT uses a priority programming system to determine which locations have the highest potential for the reduction of fatal and serious injury crashes, and return the greatest benefit for the cost of the project.

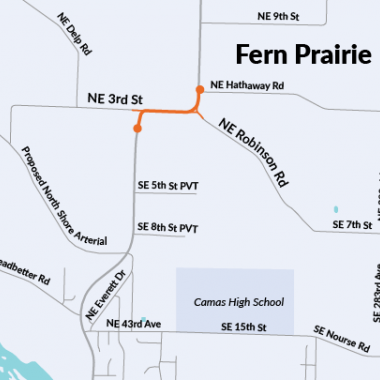

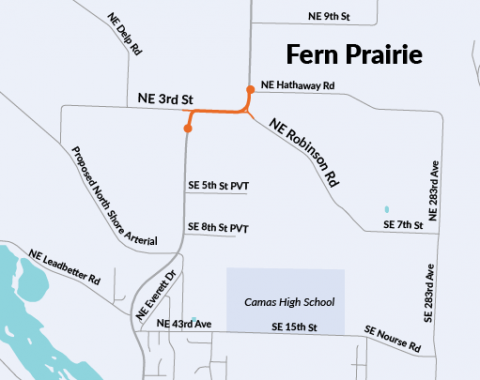

The history of run-off-the-road and intersection related crashes within the intersections at SR 500 / NE Robinson Road and NE 3rd Street puts these two intersections high on the priority list for much needed safety improvements.

With input from the community, agency partners, area schools, businesses and emergency services, WSDOT project designers will install roundabouts which help to calm traffic, increase sight distance and improve curve navigation, to significantly improve safety for all travelers along this stretch of SR 500.

Once owned and maintained by the county, the history of run-off-the-road and intersection related crashes within the intersections at SR 500 / NE Robinson Road and NE 3rd Street puts these two intersections high on the priority list for much needed safety improvements.

WSDOT's earliest records show that this roadway was originally built in 1930 by using crushed rock and asphalt oil. Over the years, WSDOT has maintained the roadway using a similar preservation technique called "chip-seal."

The chip seal process

- First, asphalt is mixed with about 30% water. This emulsified mixture is then applied to the road using a special spray truck. As soon as the liquid asphalt meets the road surface, the water starts to evaporate.

- Immediately after spraying this asphalt, a layer of crushed gravel is applied by a spreader. The gravel (or chips) has a maximum size of 3/8 inch.

- Next, the gravel is compacted and embedded into the asphalt by rubber-tired rollers. However, even with the high pressure rolling, some gravel will not become embedded in the asphalt.

- The new chip-seal surface can require up to two days to cure properly. Hot, dry weather helps speed up this process in which all of the remaining water in the emulsion evaporates and the asphalt hardens. Traffic can pass over this surface at reduced speeds during the curing process.

- After curing, the loose gravel is swept off the surface. This may take several sweepings.

The last recorded chip-seal along this stretch of roadway was done in 2016.

The current estimated cost of the project is $2.5 Million, funded entirely by the state through the crash reduction program.

View the design concept for safety improvements planned along SR 500 between the Robinson Road and 3rd Street intersections in east Clark County.