|

PGSuper

3.0

Precast-prestressed Girder Bridges

|

|

PGSuper

3.0

Precast-prestressed Girder Bridges

|

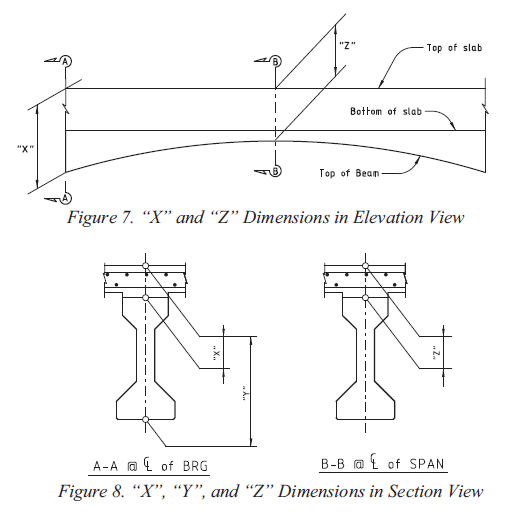

The slab offset is the vertical distance from the top of slab to the top of girder measured at the intersection of the girder and bearing centerlines. The slab offset defines the depth of the haunch at those locations as shown in figure below for an I-Beam.

NOTE: The slab offset is known in WSDOT jargon as the "A" Dimension and in TxDOT jargon as the "X" Dimension.

The slab haunch varies in depth along the length of the girder accommodating the girder camber and geometric effects of the roadway surface including superelevations, vertical curves and horizontal curves.

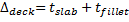

The purpose of the slab haunch is to provide a structural spacer between the bottom of the constant thickness slab and the top of the prestressed girder such that the roadway riding surface meets specified geometric requirements at the time when the bridge is put into service, and that the top of the girder does not encroach into to the deck slab. Therefore, the basic concept in determining the required slab offset is to provide a slab haunch over the girder such that the top of the girder is not more than the fillet depth below the bottom of the slab at the center of the span. This provides that the actual girder camber could exceed the calculated value by the fillet depth plus the bottom slab reinforcing cover before the top of the girder would interfere with the bottom mat of slab reinforcement.

In general, it is desirable to have points of horizontal and vertical curvature and superelevation transitions off the bridge structure as this greatly simplifies the geometric requirements on the slab haunch. However, as new bridges are squeezed into the existing infrastructure it is becoming more common to have geometric transitions on the bridge structure. Therefore, the inclusion of all geometric effects must be considered in a rigorous analysis.

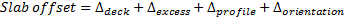

In our analysis, each geometric effect is considered independently of the others. The total geometric effect is the algebraic sum of each individual effect.

The width of the slab haunch is the width of the top flange of the girder for single top flange sections. However, tub girders have two haunches – one for each of the two top flanges, and may be non-prismatic if end blocks are present.

TIP: PGSuper's Girder Designer can find an optimal Slab Offset for you.

Well-designed slab haunches have the following characteristics:

A rigorous analysis of the slab haunch should consider the following effects:

If all cambers and deflections occur as predicted during design, the haunch depth at the point of least haunch depth will be exactly equal to the fillet dimension. However, in practice the only effects that can be computed with reliable accuracy are the roadway geometry effects. Camber, deflections, and long-term losses are generally poorly understood, and are often treated empirically. Each of these effects can be considered independently and combined to compute final haunch requirements. Individual effects are treated in detail in the following sections.

xi = Station at section i.

zi = Normal offset from the alignment to the centerline of girder at section i.

ya(xi,zi) = Elevation of the roadway surface at station xi and normal offset zi.

Per our definition; the distance between the top of the girder and the top of the roadway surface must be at least the thickness of the slab plus the fillet depth.

The Fillet is the least allowable haunch depth along a girder. This value is input by the user as part of the physical bridge description. The Fillet is used by PGSuper to compute the required “A” dimension during a specification check. During design, the fillet value can be left unchanged or it can be modified by the design algorithm if requested. If the value is modified by the design algorithm, it is set equal to the Standard Minimum Fillet Depth as specified in the Girder library.

If camber and deflection predictions are 100% accurate, a properly designed haunch will be such that the least distance between the top of girder and bottom of gross slab (haunch depth) will be exactly equal to the fillet depth.

The slab haunch must be thickened to accommodate any camber that remains in the girder after slab casting.

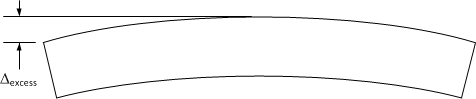

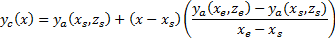

The profile effect accounts for changes in the roadway profile along the length of the girder. Profile changes include grade changes, vertical curve effects, and offset deviations between the centerline of girder and the alignment caused by flared girders and/or curvature in the alignment.

The figure above is obviously highly exaggerated. It illustrates that the profile effect is the greatest distance between the finished grade and a straight line.

Where

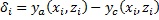

is the difference between the roadway surface directly above the centerline of the girder and the profile chord line.

The profile chord line is given by

Haunch depth demand is different depending on the type of vertical curve over the girder. Effects on haunches from Sag and Crest curve are shown below. For a typical crest curve, there is more haunch at mid-span than at the ends. A sag curve creates a minimum haunch at mid-span with a larger haunch at the ends. Stated another way: in the case of a sag vertical curve, the slab haunch must be thickened at the ends of the girder; in the case of a crown vertical curve, the slab haunch depth may be reduced. The figures below illustrate these effects.

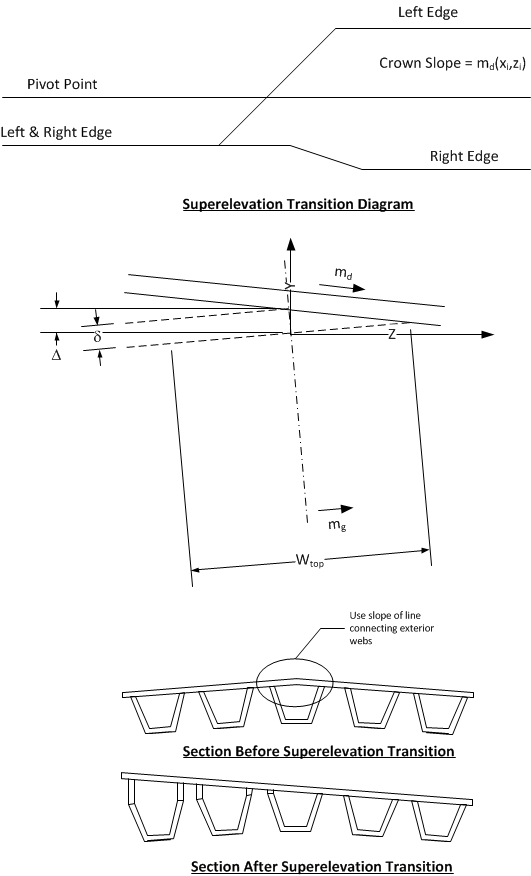

The girder orientation effect accounts for the difference in slope between the roadway surface and the top of the girder. Girders such as I-beams are typically oriented with their main axis plumb. Other girders such as U-beams, box beams, and slabs may be oriented with their main axis normal to the roadway surface. The orientation of the girder with respect to the roadway surface, and changes in the roadway surface along the length of the girder (superelevation transitions) define the Girder Orientation Effect.

where zileft = offset to left exterior mating surface and ziright = offset to right exterior mating surface.

NOTE: The mating surface is the girder surface that mates with the bottom of the slab haunch. This is commonly the top of the top flange, but not all girders have top flanges.

The required slab offset is the sum of the effects described above.

The required slab offset is rounded up to the nearest 1/4 inch (or 5 mm) before reporting and comparison with the user-input slab offset.

The minimum value of the slab offset is

The optional minimum haunch depth at bearing centerlines check puts another requirement on the controlling slab offset. This is defined in the girder library and the value is checked at both bearings as follows:

Where:

is the library-specified minimum allowable haunch depth at bearing centerlines.

These computations are for a single girder. The required slab haunch should be determined for each girder in the structure. You will typically specify the greatest required slab offset in your plans.

These computations are also limited to a single span. A different slab haunches may be needed at each end of a span. For example, if there is a long span adjacent to a short span, the long span may have considerably more camber and will require a larger slab haunch. There is no need to have the shorter spans carry all the extra concrete needed to match the longer span haunch requirements. With the wide flange girders, the volume of concrete in the haunches can add up quickly. The shorter span could have a different haunch at each end as illustrated below.

For bridges on sharp crown vertical curves, the slab haunch depth at the centerline of span can become excessive to the point where projecting girder stirrups are too short to properly engage the deck reinforcement to form a composite section. Similarly the length of leveling bolts in precast deck panels may need adjustment. A warning will be added to the slab haunch specification check when the required build-up at mid-span exceeds the slab offset by 2".

Many agencies have their own nomenclature for slab offset dimensions and TxDOT is no exception. The figure below illustrates TxDOT's "X", "Y" and "Z" dimensions. These are reported in the TxDOT Summary and Girder Schedule reports. Note that reported values for "X", "Y" and "Z" are rounded up to the nearest 1/8".